Refuse Derived Fuel (RDF)

In 2013, the CHIMIREC Group broke new ground by launching a waste with high calorific power recovery program: this waste is transformed into refuse derived fuel (RDFs - CSEs) that manufactures can use instead of fossil fuels.

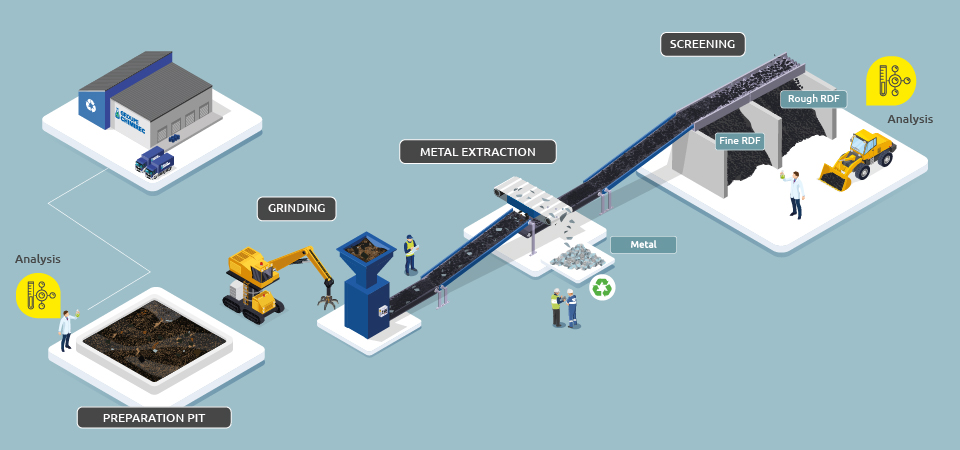

The Refuse derived fuel (RDF) treatment process

Where does high calorific waste come from?

These are unwanted paint residues, industrial and hydrocarbon sludge, glues and mastics, powders, contaminated packaging and materials, as well as filtering materials from filter processing.

What is the recovery process?

The CHIMIREC Group produces 20,000 tonnes per year of RDF (CSE) through an efficient 4-step processing process:

- Laboratory verification of waste composition and texture.

- A first grinding, followed by screening of the waste, to obtain a granularity in accordance with the specifications of the recycling process.

- A second grinding and refining of the waste to result in a finer granularity.

- The extraction of exploitable metal elements, which are oriented towards a material recovery process.

What is this recovered waste for?

They provide an energy resource to manufacturers authorized to use RDFs (CSE), such as cement producers, boilers (producers of quicklime), and electric power producers.

What is the impact to the environment?

Saving 8,000 tonnes of oil equivalent (TOE) and reducing the use of non-renewable fossil fuels.

What is the recovery rate?

100 %.