Oil filters

The CHIMIREC Group is identified as an ICPE (Installation classified for environmental protection - Installation classée pour la protection de l’environnement) dedicated to the treatment and enhancement of oil filters. It uses a process exclusive in France, a process that directly separates their three main components: oil, paper, and metal. Other units of this type are in development.

The oil filters treatment process

Where do these filters come from?

These are filters from internal combustion engines, hydraulic systems, and transmissions.

What is the recovery process?

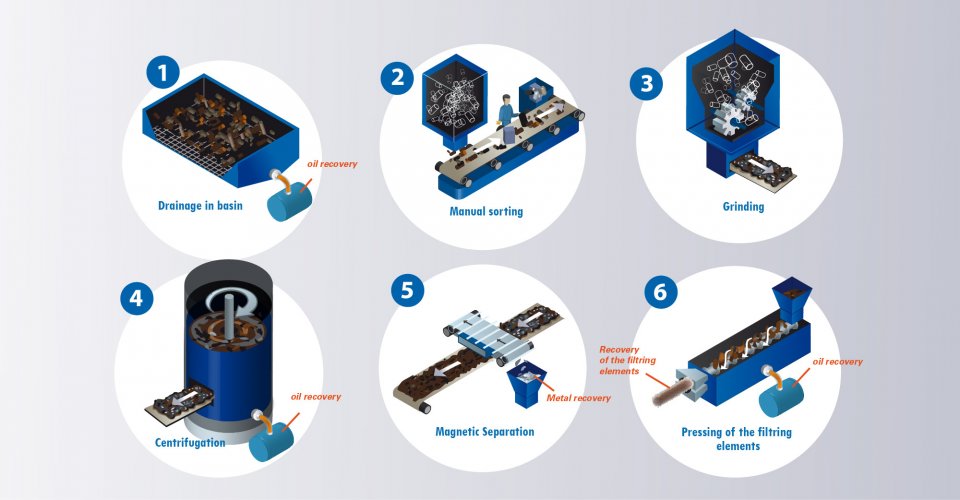

The CHIMIREC Group has developed an exclusive process in France that consists of separating the three main components of the filters (oil, paper, and metal) to recover them. The treatment is carried out in 6 stages:

- Draining in a pool and first recovery of the oil for recovery purposes

- Manual sorting to extract unwanted waste

- Grinding

- Centrifugation and hydrocarbon extraction

- Magnetic separation of the paper-metal mix, which allows the metal to be recovered

- Finally, pressing the filter elements and a second operation to recover the oil.

What are these valued filters for?

The 12,000 tonnes of filters recycled each year by CHIMIREC are recovered either as an energy resource (for oils and paper) or as a material resource (for metal).

What is the impact to the environment?

No release into the environment, no storage, no burying of the three polluted components from used filters.

What are the recovery rates?

100%: 23% for oils, 37% for paper and 40% for metal.