Sharing expertise between Aretzia and FEC Technologie

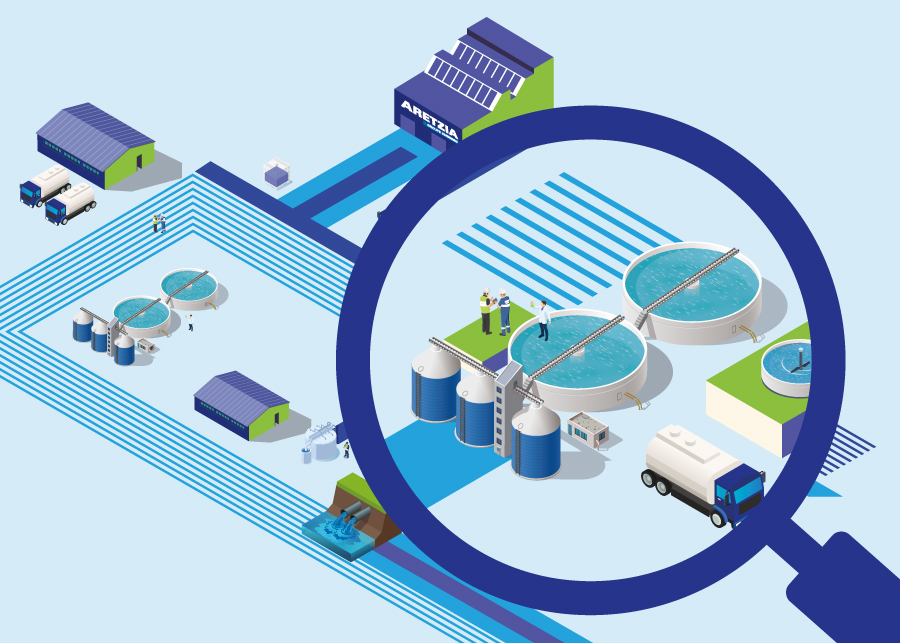

Although these two CHIMIREC subsidiaries are geographically distant from each other, with FEC Technologie in Canada and Aretzia in France, they share a common activity: the treatment of industrial effluents and their potential recovery. The recent visit to the Aretzia site by Mike Gagnon, sales manager at FEC Technologie, was of great interest with a view to development across the Atlantic.

FEC Technologie and Aretzia, two subsidiaries of the CHIMIREC Group

FEC Technologie in Quebec

Based in Magog Magog, Québec, FEC Technologie is one of the two Canadian subsidiaries of the CHIMIREC Group. Among its hazardous waste management activities, it specialises in the treatment of contaminated and oily water, for which it uses a physico-chemical process and ultrafiltration.

Aretzia in Loire-Atlantique

A subsidiary of the CHIMIREC Group since 2018, Aretzia it is located in Loire-Atlantique (44). The site has developed activities for treating industrial effluents, acids and bases, and hydrocarbon waste from industries and waste collectors in the Brittany and Pays de la Loire regions.

Its treatment activities apply to:

- Hydrocarbon-contaminated water and sludge;

- Contaminated and industrial water;

- Mineral acids and bases;

- Soluble oils;

- Metal hydroxide sludge;

- Used coolants.

Professional expertise and cutting-edge technologies

The treatment and recovery of aqueous effluents require solid technical skills on the part of employees. At the same time, it requires investment in sophisticated equipment.

These two factors combined have enabled Aretzia to achieve a high level of performance in its Profession: a recovery rate of 92% and a water reuse rate of 20%.

After analysis of the effluent by the on-site laboratory, pre-treatment removes macro-waste and sand, and separates the phases by settling.

The treatment consists of three phases:

- The primary phase is the physical-chemical treatment followed by a solid/liquid separation. The result is clear water free of metals and hydrocarbons.

- The secondary phase takes place in a biological tank where bacteria destroy the residual pollution present in the water. Aerators mechanically stir the pool, providing the oxygen necessary for bacterial life.

- The tertiary phase filters the water through sand filters and then activated carbon to remove micropollutants and non-biodegradable substances. The residues are used to manufacture Refuse Derived Fuel (RDF), which is used by cement plants as part of the energy transition.

Industrial effluents: a growing market

The agri-food, chemical and petrochemical, metallurgy, pharmaceutical and cosmetics industries, as well as the mining, aeronautics, automotive and rail industries: all these sectors generate polluting liquid waste during their operating and manufacturing processes.

These may include wastewater, oils, hydrocarbons, organic pollutants, metals, mineral acids, etc., with varying degrees of toxicity.

To protect the environment and preserve human health, the treatment of industrial effluents is subject to strict regulations, the requirements of which are likely to be tightened considering current environmental challenges.

Consequently, to meet the growing needs of local industries in both France and Canada, the CHIMIREC Group plans to equip its subsidiary FEC Technologie with more powerful filtration equipment for the management of collected hydrocarbon-contaminated water.

Published : 2025-12-18