Treatment of waste contaminated with Polychlorobiphenyls (PCBs)

A unique, innovative and environmentally-friendly process

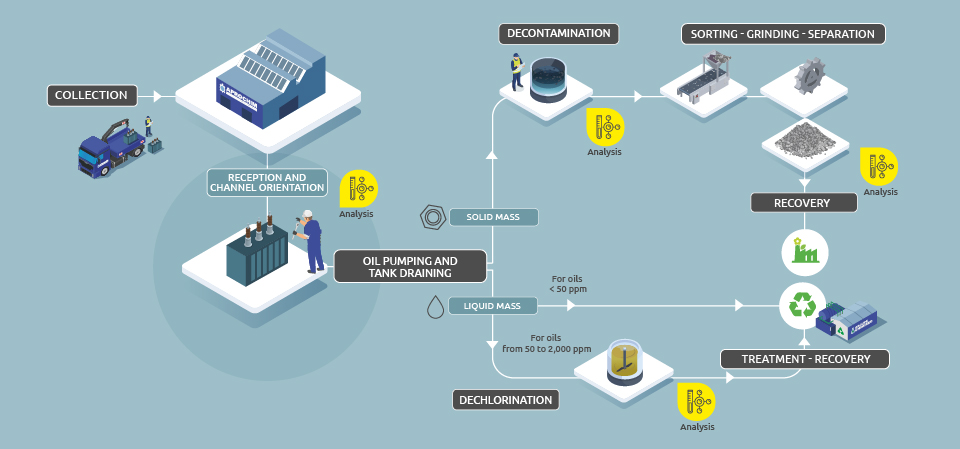

Every piece of equipment entering our site is identified and analysed, ensuring perfect management of the risks associated with PolyChloroBiphenyls, even for equipment deemed to be non-contaminated. In this way, we can guarantee our customers safe, controlled risk management.

At our APROCHIM facilities, we begin the process of dismantling equipment by treating the liquids. Our expertise in the treatment of clear oils, whether contaminated by PCBs or not, enables us to treat them effectively. Our dechlorination unit can treat liquids containing up to 2000 ppm of PCBs, with a view to subsequent recovery at another facility within the Group: CHIMIREC PPM

When it comes to solids, we dismantle and degrease them without using thermal processes or solvents, thereby reducing the risks to our employees and the environment. Our primary objective remains the recovery of fractions from the dismantling of transformers, in compliance with a quality control and monitoring plan for these materials.

The CHIMIREC Group's process aims to neutralise pollutants, which will either be dechlorinated internally or incinerated by our partner specialising in incineration. Decontaminated products containing less than 50 ppm and separated, such as steel, copper or ferro-silicon wafers, will be recycled in specialised channels.

Expertise and an eco-logical approach

Thanks to its recognised expertise, our subsidiary APROCHIM handles the collection, treatment and recycling of waste contaminated by Polychlorobiphenyls.

- Analysis : Before providing a quote or upon receipt at our site, we carry out an analysis of your waste using X-ray fluorescence spectrometry to detect PCBs and gas chromatography to determine their concentration.

- Inspections : Our laboratory checks the recoverable materials for residual contamination and monitors the environmental impact of our decontamination activities.

- Collection : We collect contaminated materials in strict compliance with regulations on the transport of hazardous materials, using a fleet of trucks that comply with ADR standards.

- Treatment : As the designer and owner of the dechlorination treatment process, we offer a sustainable decontamination solution that protects both the environment and public health.

- Recovery: Decontaminated waste, containing less than 50 ppm, is sorted and recycled in partner treatment facilities, guaranteeing optimum waste management.

Treatment capacity: our facility can treat up to 8,000 tonnes per year of PCB-contaminated solid materials and mineral oils.

(Prefectoral decree no. 2006-P-953 bis of June 30, 2006).

Our environmentally-friendly, high-performance process guarantees atmospheric emissions well below European regulatory standards. What's more, it significantly reduces health risks for employees, while minimising energy consumption.

Our triple certification for Quality, Safety and the Environment testifies to our commitment to responsible practices.

Contact

APROCHIM

ZI de La Promenade

53290 GREZ-EN-BOUERE

Phone : 02 43 09 14 50

Contact: Cédric DERRIEN - Business Manager

Mail: contact@aprochim.fr

Phone : 07 89 02 06 43