CHIMIREC Avrasya: Time for CAPM !

The computer-aided production management system (CAPM) has been installed at our Turkish subsidiary, CHIMIREC Avrasya. An initiative by our teams to further improve performance on the Energy Substitution Fuel (ESF) production line.

The context: strong demand for alternative fuels

In France, production of Energy Substitution Fuel (ESF) began in 2013 at the CHIMIREC Javené site. Several units were later deployed at the CHIMIREC Socodeli Beaucaire, CHIMIREC Avrasya in Turkey and CHIMIREC Morocco subsidiaries.

In recent years, faced with the challenges of the energy transition and the decarbonisation of industry, ESF has provided an alternative solution to fossil fuels, and is particularly popular with the cement industry.

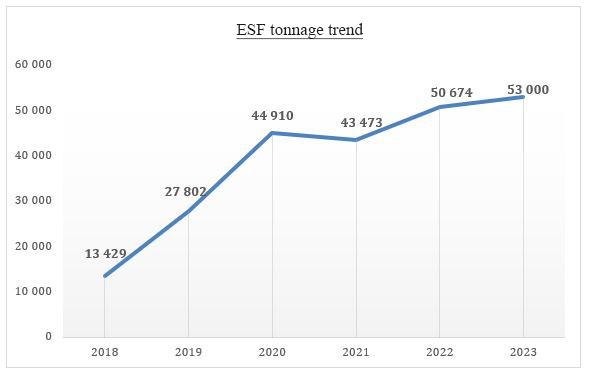

In Turkey, where the construction sector is booming, the cement industry naturally has colossal needs for ESF. Benefiting from the expertise acquired by the CHIMIREC Group in France, our Turkish subsidiary has carved out a place for itself in this buoyant market. Thanks to the generic quality of the ESF produced and its ability to adapt to the specifications of its cement customers, CHIMIREC Avrasya is now the leading ESF supplier in the Turkish market.

Today’s challenge is to keep up with demand. It was with the aim of maintaining a stable level of productivity, and even increasing it, that the CHIMIREC Avrasya teams set up the CAPM system at their Gebze site.

One solution : CAPM and its undeniable advantages

Increasing production capacity on the ESF production line involves a number of requirements. Only a detailed and precise computer analysis can provide the information needed to improve performance.

-

Maintenance : to ensure the reliability of production tools and avoid any risk of breakage that could lead to a line stoppage, the computerised control system sends alerts where necessary, and enables machine maintenance dates to be scheduled.

-

Productivity : CAPM acts as a supervisory tool, analysing the production flow and identifying when productivity is falling. The flow meter is a counter that displays results by the minute. This means that CAPM enables operators to be better trained, giving them optimum control of the production chain. Performance and productivity gains are estimated at 15% to 20%.

In France, the roll-out of CAPM to all subsidiaries

The roll-out of CAPM to all French subsidiaries is currently under analysis. Carried out in close collaboration with the Information Systems Department, this is a major operation. It will involve global supervision of a large number of indicators. Implementation is planned over the next few months, in conjunction with the launch of the ESF production line at the CHIMIREC Aulnay-sous-Bois site.

CHIMIREC Avrasya FIGURES

- 2023 : 53 000 tonnes tonnes of waste recovered in ESF.

- Objective : 100 000 tonnes per year with the creation of the second site.

Published : 2023-11-17